The Technology Research Center

At Sangsin Brake, we don’t just develop 200+ new products annually. We work to test and perfect our portfolio of OEM brake pads and brake replacement products with constant research and development. We accomplish this at our very own state-of-the-art Technology Research Center where we perform brake-specific testing on our large assemblage of dynamometers.

Testing Equipment

Our research center is replete with innovative testing equipment designed and engineered by Sangsin that other auto manufacturers around the world are adopting for their facilities.

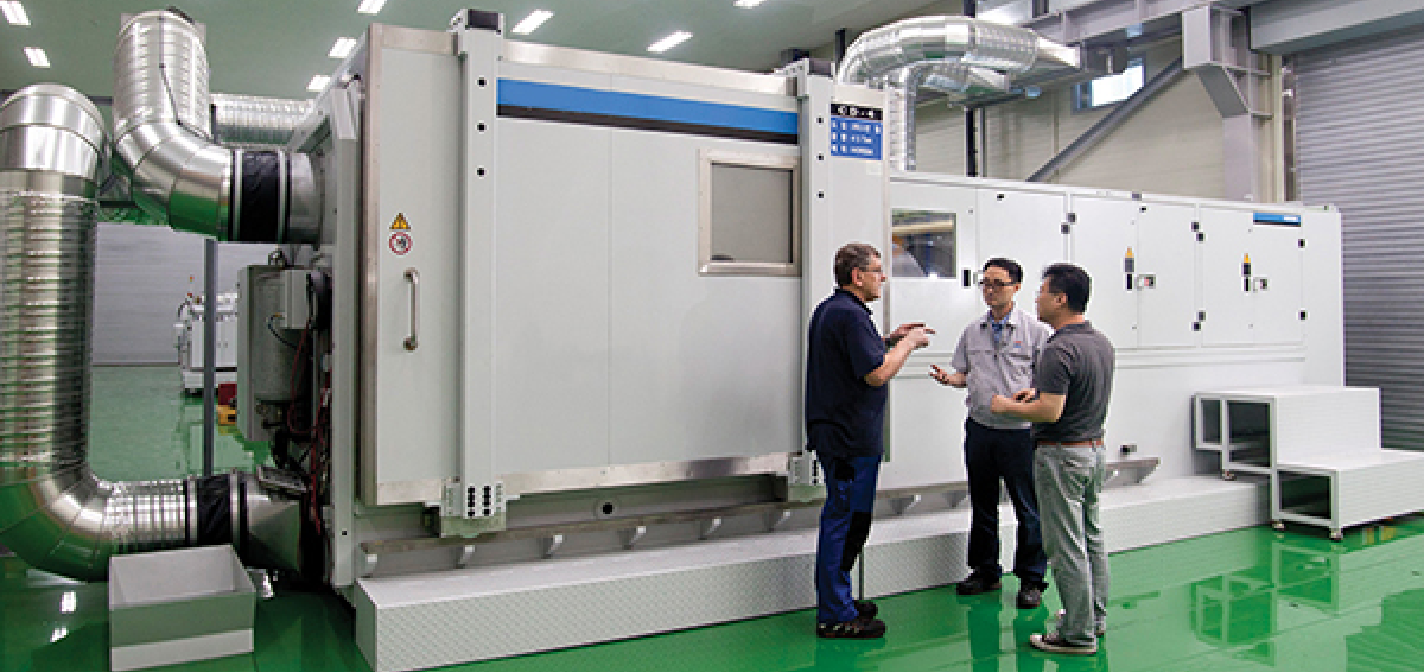

Chassis Noise Brake Dynamometer

- Realizing actual driving and braking conditions with a real car

- Controlling environmental conditions(temperature/humidity)

- Anechoic chamber

- Analyzing brake NVH (Noise, Vibration, Harshness) test

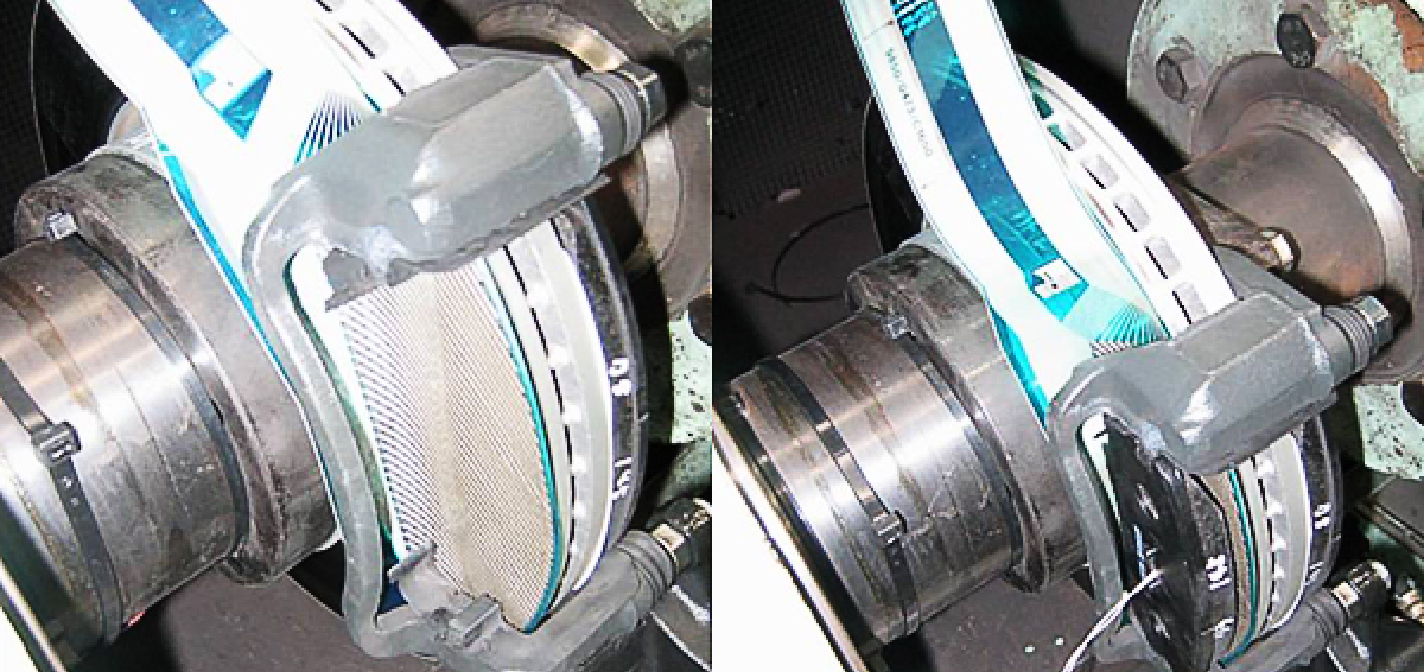

Performance Dynamometer

- Durability and life testing; calculates wear data and life for pads and rotors

- Realizing the brake system for driving and braking in each of the brake module: a ¼ car, and a ½ car unit

- Evaluating the brake performance, abrasion, and NVH tests of the brake system

- Controlling environmental conditions (temperature/humidity)

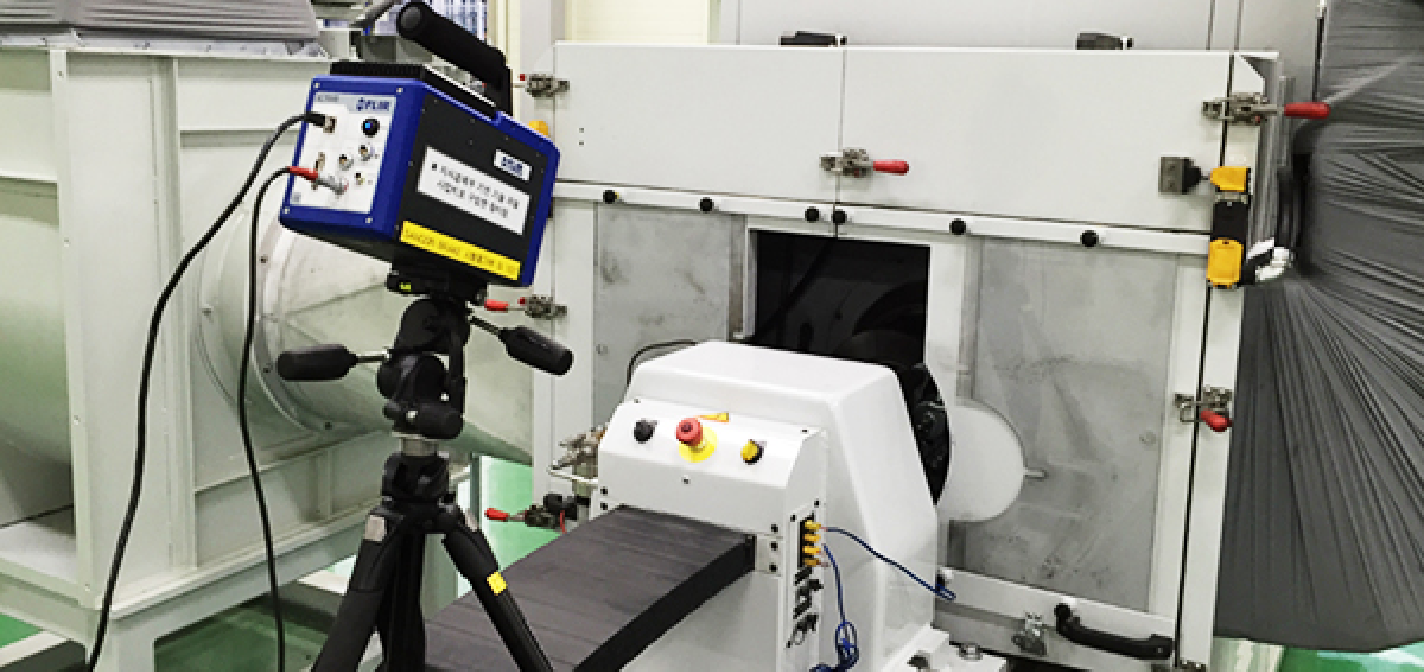

Thermographic Camera

- Analyzing the thermal behavior of the disc at braking

- Able to measure the temperature of a high-speed rotating disc

- Analyzing the distribution of temperature for noncontact types

Multichannel Analyzer (DAQ)

- Measuring and analyzing NVH (Noise, Vibration, Harshness)

- Modal Analysis, ODS (Operational Deflection Shape), Frequency Analysis etc.

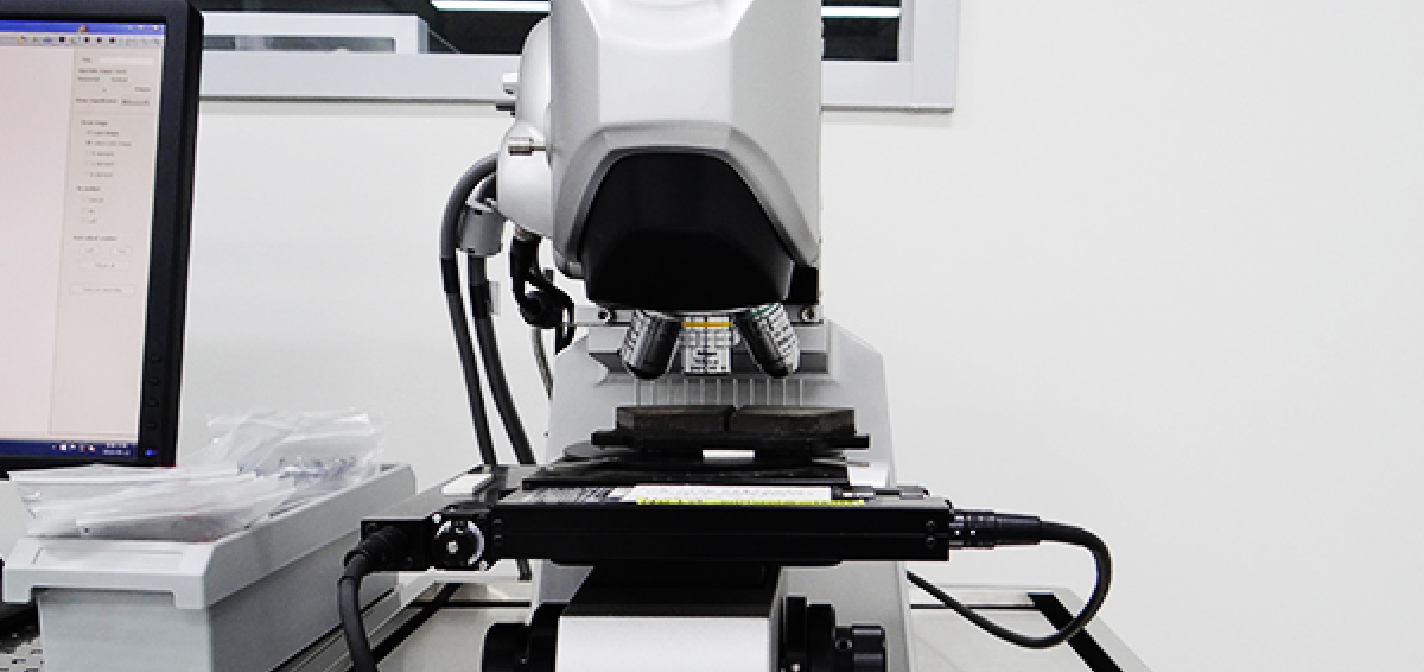

Measurement of the Surface Pressure of Friction Materials

- Analyzing the distribution of contact stresses between the disc and the brake pad

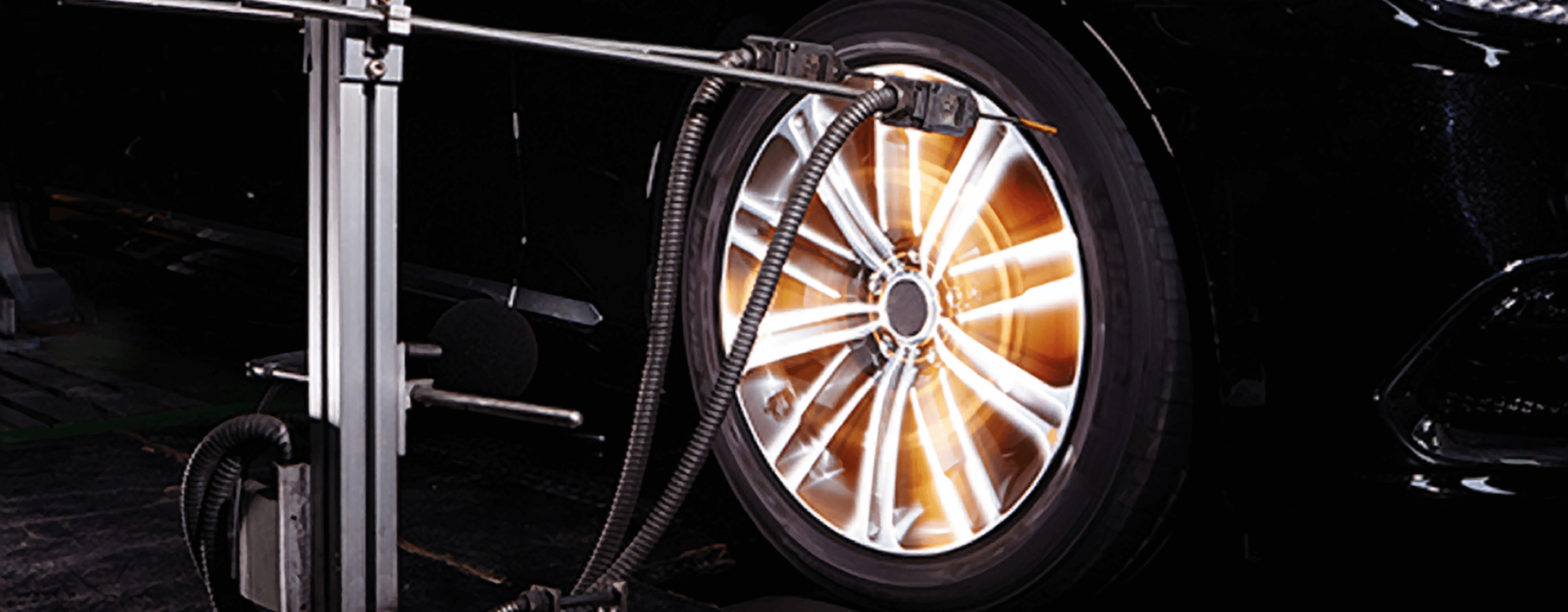

Real Car Performance DAQ

- Attached to the real car for brake-related testing

- Collecting and analyzing brake performance and NVH data